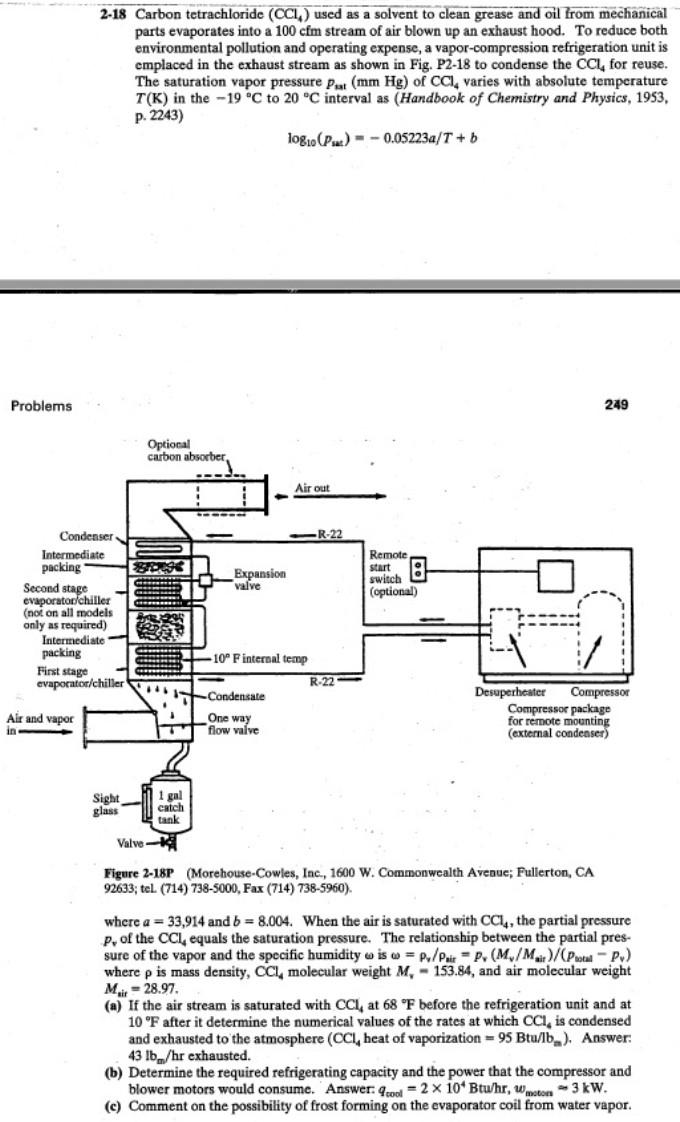

2-18 Carbon tetrachloride (CCI) used as a solvent to clean grease and oil from mechanical parts evaporates into a 100 cfm stream of air blown up an exhaust hood. To reduce both environmental pollution and operating expense, a vapor-compression refrigeration unit is cmplaced in the exhaust stream as shown in Fig. P2-18 to condense the CCL for reuse. The saturation vapor pressure Pat (mm Hg) of CCI, varies with absolute temperature T(K) in the -19 °C to 20 °C interval as (Handbook of Chemistry and Physics, 1953, p. 2243) log10 (P) -- 0.05223a/T + b Problems 249 Optiona! carbon absorber, Air out -R-22 Remote Expansion valve switch (optional) Condenser Intermediate packing Second stage evaporator chiller (not on all models only as required) Intermediate packing First stage evaporator/chiller 10° F internal temp R.22 Condensate Air and vapor One way Desuperheater Compressor Compressor package for remote mounting (external condenser) flow valve Sight glass 1 ga! catch Valve- Figure 2-18P (Morehouse-Cowles, Inc., 1600 W. Commonwealth Avenue; Fullerton, CA 92633; tel. (714) 738-5000, Fax (714) 738-5960). where a = 33,914 and b = 8.004. When the air is saturated with CCI, the partial pressure P. of the CCI, equals the saturation pressure. The relationship between the partial pres- sure of the vapor and the specific humidity wis w = p / Pois = p. (M./M.)/(Poul - P) where p is mass density, CCL, molecular weight M, - 153.84, and air molecular weight M.-28.97. (a) If the air stream is saturated with CCI, at 68 °F before the refrigeration unit and at 10'F after it determine the numerical values of the rates at which CCI, is condensed and exhausted to the atmosphere (CCI, heat of vaporization = 95 Btu/lb.). Answer: 43 lb/hr exhausted. (b) Determine the required refrigerating capacity and the power that the compressor and blower motors would consume. Answer: 4cool = 2 x 10* Btu/hr, Weston - 3kW. (e) Comment on the possibility of frost forming on the evaporator coil from water vapor.

没有找到相关结果