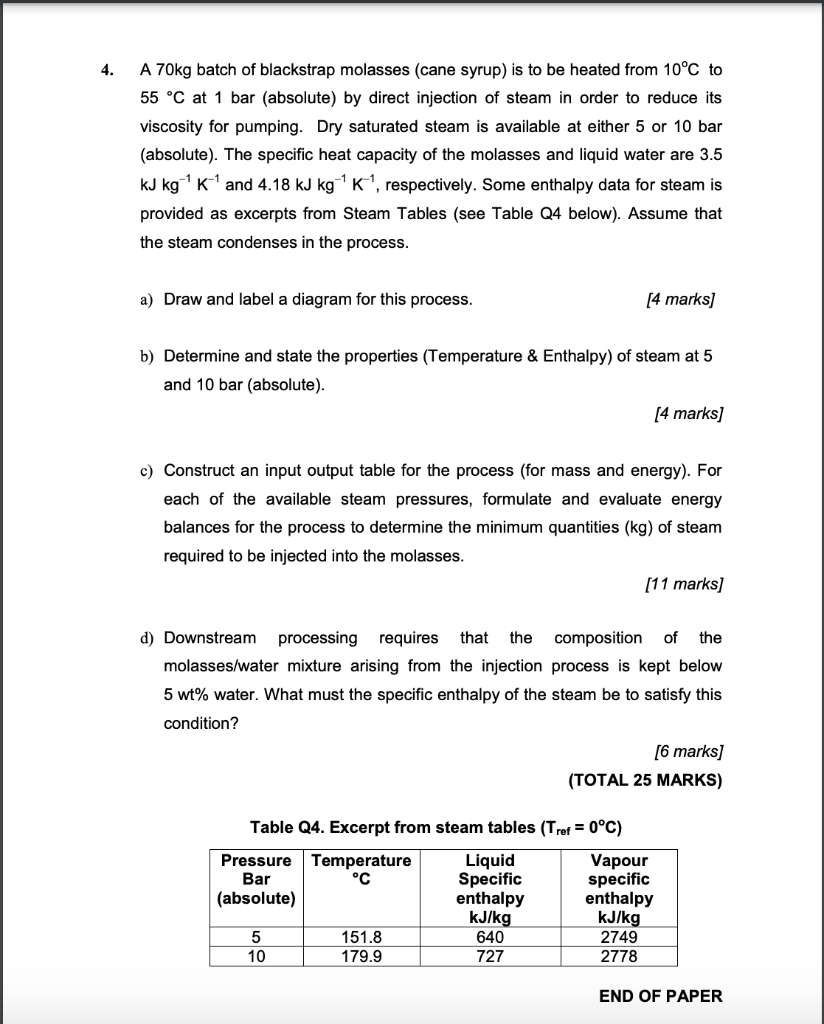

4. A 70kg batch of blackstrap molasses (cane syrup) is to be heated from 10°C to 55 °C at 1 bar (absolute) by direct injection of steam in order to reduce its viscosity for pumping. Dry saturated steam is available at either 5 or 10 bar (absolute). The specific heat capacity of the molasses and liquid water are 3.5 kJ kg 'K' and 4.18 kJ kg 'K', respectively. Some enthalpy data for steam is provided as excerpts from Steam Tables (see Table Q4 below). Assume that the steam condenses in the process. a) Draw and label a diagram for this process. [4 marks] b) Determine and state the properties (Temperature & Enthalpy) of steam at 5 and 10 bar (absolute). [4 marks] c) Construct an input output table for the process (for mass and energy). For each of the available steam pressures, formulate and evaluate energy balances for the process to determine the minimum quantities (kg) of steam required to be injected into the molasses. [11 marks] d) Downstream processing requires that the composition of the molasses/water mixture arising from the injection process is kept below 5 wt% water. What must the specific enthalpy of the steam be to satisfy this condition? [6 marks) (TOTAL 25 MARKS) Table Q4. Excerpt from steam tables (Tref = 0°C) Pressure Temperature Liquid Vapour Bar °C Specific specific (absolute) enthalpy enthalpy kJ/kg kJ/kg 5 151.8 640 2749 10 179.9 727 2778 END OF PAPER

没有找到相关结果