Please be neat and legible to receive rating. thank you

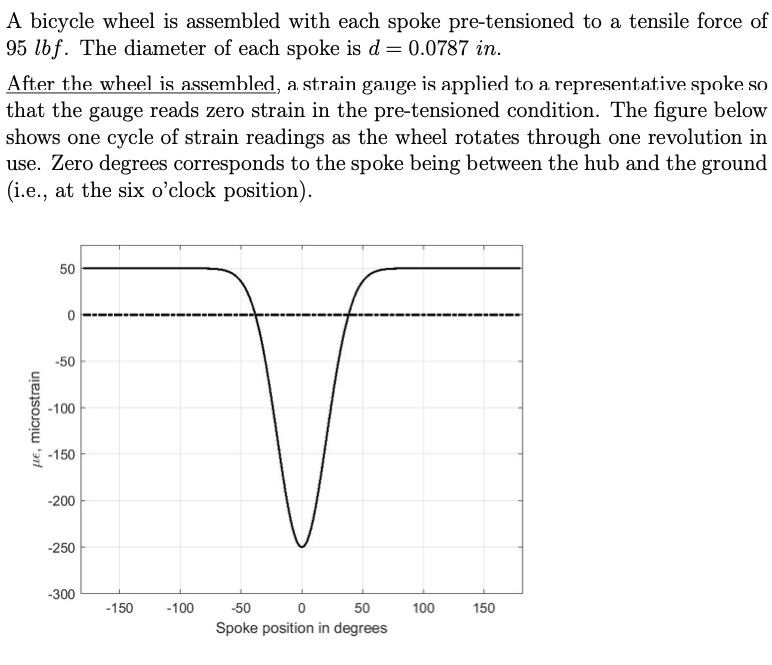

A bicycle wheel is assembled with each spoke pre-tensioned to a tensile force of 95 lbf. The diameter of each spoke is d= 0.0787 in. After the wheel is assembled, a strain gauge is applied to a representative spoke so that the gauge reads zero strain in the pre-tensioned condition. The figure below shows one cycle of strain readings as the wheel rotates through one revolution in use. Zero degrees corresponds to the spoke being between the hub and the ground (i.e., at the six o'clock position). 50 0 -50 -100 fle, microstrain -150 -200 -250 -300 - 150 -100 -50 100 150 0 50 Spoke position in degrees

(a) Carefully re-read the presented information and use Hooke's Law to deter- mine the minimum and maximum stress in the spoke. Note that the vertical axis in the figure above reads in units of micro-strain. You may use a value of E = 30e6 lbflina. (b) Convert the preceding values to mid-range and alternating stresses. (C) Assume that the spoke material has an ultimate strength of 50 ksi, and a yield strength of 40 ksi and is cold-drawn. Draw a modified Goodman diagram showing both the yield line and the fatigue line. (d) Show the given stress state and draw the load line. Determine the factors of safety with respect to fatigue and to first-cycle yielding.

没有找到相关结果